MS45 MAF Transfer Curve Comparison

-

Renovelo

- Site Admin

- Posts: 316

- Joined: Thu Aug 08, 2013 7:02 pm

MS45 MAF Transfer Curve Comparison

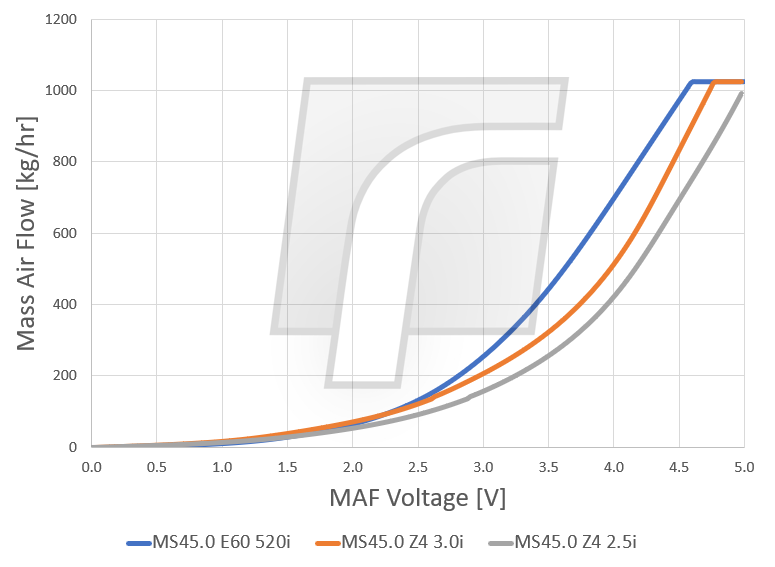

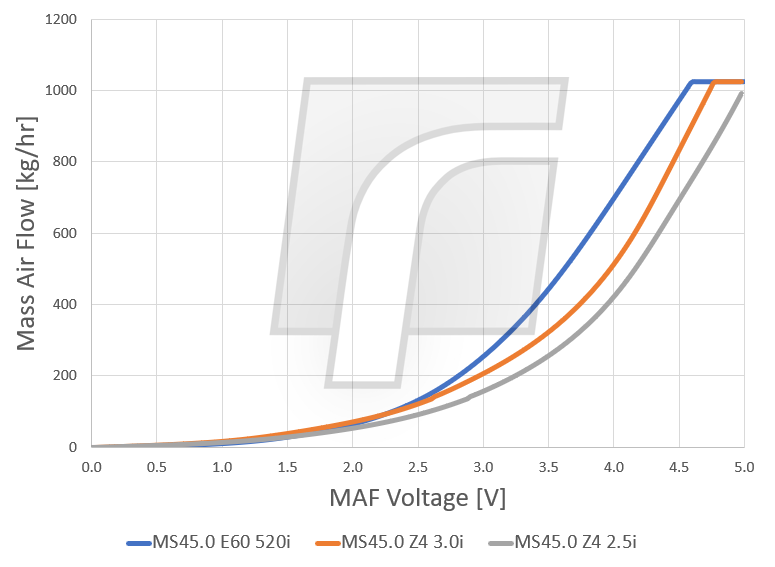

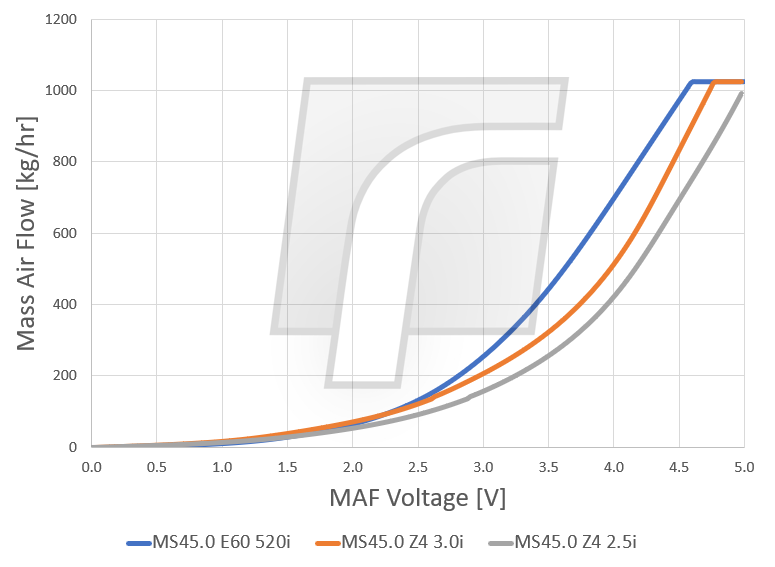

BMW used the MS45 DME across a wide range of vehicles when considering both MS45.0 and MS45.1. It covered several chassis designations (E46, E60, E83, E85/E86) and several engine displacements. Just to show how important it is to choose the correct base tune for your vehicle, we extracted the MAF transfer curves from several stock tunes and put them on the same graph. Feel free to use this data if you're using a MAF sensor from one of these vehicles or if you're planning to tune for a bigger MAF sensor. Keep in mind that the 1024kg/hr limit is also present in MS45. However, we have dug through the disassembly of these DMEs and think we know of a way to bypass this just like MS42/MS43. We're just waiting for a customer who can surpass 1024kg/hr, has a larger MAF available, and is willing to help us test.

You do not have the required permissions to view the files attached to this post.

-

snelan

- Posts: 4

- Joined: Wed Oct 09, 2019 8:35 am

Re: MS45 MAF Transfer Curve Comparison

I have an ASA TM12 supercharger running around 11PSI on my 2004 ZHP (MS45.1). I'll do some logging to see if I exceed 1024! This would be a great thing to have for those of us who would like to push the cars even further.

-

Renovelo

- Site Admin

- Posts: 316

- Joined: Thu Aug 08, 2013 7:02 pm

Re: MS45 MAF Transfer Curve Comparison

Yeah, definitely let us know! Do you have access to a larger MAF already?

-

snelan

- Posts: 4

- Joined: Wed Oct 09, 2019 8:35 am

Re: MS45 MAF Transfer Curve Comparison

I don't at the moment. Do you have any recommendations?

-

Renovelo

- Site Admin

- Posts: 316

- Joined: Thu Aug 08, 2013 7:02 pm

Re: MS45 MAF Transfer Curve Comparison

The MS43 community seems to have latched onto the Audi RS4 MAF. It has many good qualities which make it ideal: cheap (~$115), 3.5" diameter, high flow rate (~1800kg/hr). We don't have any personal experience with this MAF, but it sounds pretty good. We have experience with the infamous PMAS HPX MAF. It's more capable than the RS4 MAF (over 3000kg/hr in a 3.5" intake), but it comes with a slightly higher price tag ($212). Either would work well for you and both have published curves.

Let us know what your logs show with the stock MAF. Also, let us know if you're interested in testing the firmware hack we have in mind.

Let us know what your logs show with the stock MAF. Also, let us know if you're interested in testing the firmware hack we have in mind.

-

Juuso

- Posts: 4

- Joined: Thu Feb 20, 2020 3:03 am

Re: MS45 MAF Transfer Curve Comparison

I have Audi RS4(b5) MAF in my EU E60 520i(m54b22 Siemens MS45) turbo. It was hard to find Flow/Voltage curve for it and curve which I found from internet wasn't perfect. In stock n/a conditions it showed ~50kg/hr higher amount of air just before rpm limiter than stock MAF but I have proceed with it. Now at the moment I have 0.4-0.5bar boost and it already showed me 998kg/hr which seems a bit high to me but is it?

I'm going to raise boost to 1bar when dme calculations is capable for that and I have solved my other fueling issue which starts from 5500rpm->

I'm going to raise boost to 1bar when dme calculations is capable for that and I have solved my other fueling issue which starts from 5500rpm->

-

snelan

- Posts: 4

- Joined: Wed Oct 09, 2019 8:35 am

Re: MS45 MAF Transfer Curve Comparison

I may just go ahead and order the RS4 MAF in this case. I'm wondering if I'll have to do something about the IAT integrated into the stock MAF though. I'll get back to you when possible with my logs! And I would be 100% open to testing the firmware hack.Renovelo wrote: ↑Mon Mar 16, 2020 7:41 pm The MS43 community seems to have latched onto the Audi RS4 MAF. It has many good qualities which make it ideal: cheap (~$115), 3.5" diameter, high flow rate (~1800kg/hr). We don't have any personal experience with this MAF, but it sounds pretty good. We have experience with the infamous PMAS HPX MAF. It's more capable than the RS4 MAF (over 3000kg/hr in a 3.5" intake), but it comes with a slightly higher price tag ($212). Either would work well for you and both have published curves.

Let us know what your logs show with the stock MAF. Also, let us know if you're interested in testing the firmware hack we have in mind.

-

Renovelo

- Site Admin

- Posts: 316

- Joined: Thu Aug 08, 2013 7:02 pm

Re: MS45 MAF Transfer Curve Comparison

https://forum.e46fanatics.com/showthread.php?t=1113160

https://www.ms4x.net/index.php?title=Fo ... n_Upgrades

Let us know when you've completed the swap and we can test the MS45.1 firmware hack with you. This includes getting your car running properly with the new MAF (retuning the MAF curve). We're planning to test MS45.0 with Juuso who has already done this on his turbo setup: viewtopic.php?f=17&t=1708

https://www.ms4x.net/index.php?title=Fo ... n_Upgrades

Let us know when you've completed the swap and we can test the MS45.1 firmware hack with you. This includes getting your car running properly with the new MAF (retuning the MAF curve). We're planning to test MS45.0 with Juuso who has already done this on his turbo setup: viewtopic.php?f=17&t=1708

- josh@severntuning

- Posts: 17

- Joined: Thu Jul 11, 2019 8:12 pm

Re: MS45 MAF Transfer Curve Comparison

1. The IAT sensor is integrated into both the stock MS45 and the RS4 MAF sensor. You'll need to compare the curves of both sensors and ensure they are close. In theory you should be able to use the RS4 MAF sensor's IAT sensor without issue. IIRC they are both 5 wire setups, though I haven't had a chance to do this on a customer's car yet. I wasn't able to get an HPX MAF to work on a customer's car I was tuning remotely, although I suspect that sensor was DOA. The curves HPX sent were wrong too, and I only caught it because I physically measured the pipe diameter I purchased.

2. How are you scaling the injectors? There are several ways, including adjust the global (time) correction factor; individual cylinder (time) correction factors (best if you have actual flow data for your setup); the correction factor that relates mg/stk to injector pulsewidth; or the 12x16 and 10x12 compensation tables for each site (the hardest way IMHO). You could also alter the MAF curve itself, but that's definitely not ideal and will lead to other issues with incorrect mg/stk calculations. IIRC, the global time factor is the same name as MS45 (www.ms4x.net for reference).

3. Have you added in injector deadtimes?

4. You can't copy/paste the RS4 MAF curve into the ECU. You need to align it first. At 4.6-5V, the MS45 ECU thinks you're flowing 1024 kg/hr, but the RS4 MAF is calibrated for 1800 kg/hr at 4.6-5V. If you're not using the MAF hack, the curve should peak super early. At 0.5 bar of boost, you should be fine with the stock MAF as long as it's a draw-thru setup. Don't use the stock MAF on a blow-thru setup or it *will* prematurely fail (ask me how I know).

5. Don't forget about the intake manifold tables, which absolutely must be adjusted. Timing should be pulled back a few degrees (denser charge = flame front will move more quickly, and there's a higher likelihood of knock), and ideally knock tables will be adjusted, since the stock are not built with boost in mind. At 0.5 bar you should be ok on the stock tables, but no more boost than that.

My personal car is still at my shop with a cam timing issue. Once it's out I should be able to help more, as I'm planning to do the RS4 MAF due to the integrated IAT sensor. I currently run Porsche 997tt injectors and an AFD flex fuel kit, and the car feels like it came from the factory with the injectors and my supercharge @ 10 psi... so it's absolutely possible to get it running like factory.

2. How are you scaling the injectors? There are several ways, including adjust the global (time) correction factor; individual cylinder (time) correction factors (best if you have actual flow data for your setup); the correction factor that relates mg/stk to injector pulsewidth; or the 12x16 and 10x12 compensation tables for each site (the hardest way IMHO). You could also alter the MAF curve itself, but that's definitely not ideal and will lead to other issues with incorrect mg/stk calculations. IIRC, the global time factor is the same name as MS45 (www.ms4x.net for reference).

3. Have you added in injector deadtimes?

4. You can't copy/paste the RS4 MAF curve into the ECU. You need to align it first. At 4.6-5V, the MS45 ECU thinks you're flowing 1024 kg/hr, but the RS4 MAF is calibrated for 1800 kg/hr at 4.6-5V. If you're not using the MAF hack, the curve should peak super early. At 0.5 bar of boost, you should be fine with the stock MAF as long as it's a draw-thru setup. Don't use the stock MAF on a blow-thru setup or it *will* prematurely fail (ask me how I know).

5. Don't forget about the intake manifold tables, which absolutely must be adjusted. Timing should be pulled back a few degrees (denser charge = flame front will move more quickly, and there's a higher likelihood of knock), and ideally knock tables will be adjusted, since the stock are not built with boost in mind. At 0.5 bar you should be ok on the stock tables, but no more boost than that.

My personal car is still at my shop with a cam timing issue. Once it's out I should be able to help more, as I'm planning to do the RS4 MAF due to the integrated IAT sensor. I currently run Porsche 997tt injectors and an AFD flex fuel kit, and the car feels like it came from the factory with the injectors and my supercharge @ 10 psi... so it's absolutely possible to get it running like factory.

-

Juuso

- Posts: 4

- Joined: Thu Feb 20, 2020 3:03 am

Re: MS45 MAF Transfer Curve Comparison

1. I have checked they have same resistance in 20celsius and from Live Data I have checked in cold mornings it seems to be pretty accurate. Higher temps I can't be sure yet as we have cold weather here at the moment and I haven't tested they for example 35-50 celsius environment but yeah that's good point which I should do to be sure curves match in higher temps.

2. I have scaled injectors in "Global injection time correction". I have set which have been flow tested and matched set of injectors so I knew exact flow rates for new injectors and I found flow test measurements for same type of injectors which I had stock and I made calculation between them.

"the correction factor that relates mg/stk to injector pulsewidth; or the 12x16 and 10x12 compensation tables for each site (the hardest way IMHO)"

I think you mean by 12x16 compensation table ip_mff_cor_2 and ip_mff_cor_1 but what tables you mean by 10x12? Those 12x16 adjust have been easy when car was N/A and also now when it's boosted but for some reason ecu just doesn't raise injection time much as needed after 5500rpm and it start to go lean and AFR is 13-13.5 before 6000rpm and it get worse over 6000rpm. I took video from live data while I was in dyno but there can't see same time rpm and injection time but it shows end of the pull injection time start to drop and that time we took pulls only to around 6000rpm not untill limiter because it went lean so badly.

Here is some figures from Load/RPM/Boost(bar) in WOT pull in dyno: 594.8/4000/0.3 , 601.4/4512/0.31 , 621.5/5056/0.33 , 637.3/5504/0.34 , 644.0/5600/0.34 , 629.6/6016/0.4 , 604.0/6240/0.4. At dyno I run without boost tee in that moment and I have 0.3bar spring in my Tial 38mm wastegate. Wastegate obviously opened in those pulls at 3800-4000rpm because there is litle bump in boost chart which dyno data collection have draw.

3. I haven't but I did now.

4. Why I can't adjust it to conversion table for MAF value as isn't that the table where ECU calculates airflow/V right? I didn't say I used it straight which I found from wiki because there is different kghr/V steps in chart than MS45 have so I first wrote it out in excel to get it right. How do you mean I have to align it first as I have RS4 MAF sensor in it original tube not different size tubing? MAF hack is to get ecu capable calculate more than 1024kg/hr right? For example it doesn't really matter if MAF Voltage is 3 or 4.5V at 268.59kg/hr long as it match up in id_maf_tab(coversion table for MAF value) where ecu read kg/hr value from voltage, right?

After all I have m54b22 EU spec MS45 which have whole different MAF than US/EU spec Z4 m54b25 MS45 which tune I'm currently using as base tune. For start I modified MAF table for my stock MAF values to get it running correct when car was full stock except US Z4 2.5i tune.

In my conversion at the moment I use RS4 MAF as blow thru because its basicly imposible to get it to turbo inlet which is lowmount setup in my car because I don't want to delete AC, I'm aware problems which might appear after some time with oil in charge pipes.

5. At this point I haven't adjusted them as car still runs nicely with stock 2.5 intake manifold tables. I have read many times your big and helpful post from these tables and tuning them and I want to thank you for posting it! I actually have already calculated everything with those instructions for 1bar but obviously it can't be used yet. I have modified ignition tables when I was in dyno. And I think I don't have problem with torque limiting by ecu as my throttle setpoint stay in 80.98 from 3000rpm to +6000rpm until lift gas pedal?

Actually I think we run same injectors, Bosch 0280158123? My target is 14-15psi but we will see how I get there.

2. I have scaled injectors in "Global injection time correction". I have set which have been flow tested and matched set of injectors so I knew exact flow rates for new injectors and I found flow test measurements for same type of injectors which I had stock and I made calculation between them.

"the correction factor that relates mg/stk to injector pulsewidth; or the 12x16 and 10x12 compensation tables for each site (the hardest way IMHO)"

I think you mean by 12x16 compensation table ip_mff_cor_2 and ip_mff_cor_1 but what tables you mean by 10x12? Those 12x16 adjust have been easy when car was N/A and also now when it's boosted but for some reason ecu just doesn't raise injection time much as needed after 5500rpm and it start to go lean and AFR is 13-13.5 before 6000rpm and it get worse over 6000rpm. I took video from live data while I was in dyno but there can't see same time rpm and injection time but it shows end of the pull injection time start to drop and that time we took pulls only to around 6000rpm not untill limiter because it went lean so badly.

Here is some figures from Load/RPM/Boost(bar) in WOT pull in dyno: 594.8/4000/0.3 , 601.4/4512/0.31 , 621.5/5056/0.33 , 637.3/5504/0.34 , 644.0/5600/0.34 , 629.6/6016/0.4 , 604.0/6240/0.4. At dyno I run without boost tee in that moment and I have 0.3bar spring in my Tial 38mm wastegate. Wastegate obviously opened in those pulls at 3800-4000rpm because there is litle bump in boost chart which dyno data collection have draw.

3. I haven't but I did now.

4. Why I can't adjust it to conversion table for MAF value as isn't that the table where ECU calculates airflow/V right? I didn't say I used it straight which I found from wiki because there is different kghr/V steps in chart than MS45 have so I first wrote it out in excel to get it right. How do you mean I have to align it first as I have RS4 MAF sensor in it original tube not different size tubing? MAF hack is to get ecu capable calculate more than 1024kg/hr right? For example it doesn't really matter if MAF Voltage is 3 or 4.5V at 268.59kg/hr long as it match up in id_maf_tab(coversion table for MAF value) where ecu read kg/hr value from voltage, right?

After all I have m54b22 EU spec MS45 which have whole different MAF than US/EU spec Z4 m54b25 MS45 which tune I'm currently using as base tune. For start I modified MAF table for my stock MAF values to get it running correct when car was full stock except US Z4 2.5i tune.

In my conversion at the moment I use RS4 MAF as blow thru because its basicly imposible to get it to turbo inlet which is lowmount setup in my car because I don't want to delete AC, I'm aware problems which might appear after some time with oil in charge pipes.

5. At this point I haven't adjusted them as car still runs nicely with stock 2.5 intake manifold tables. I have read many times your big and helpful post from these tables and tuning them and I want to thank you for posting it! I actually have already calculated everything with those instructions for 1bar but obviously it can't be used yet. I have modified ignition tables when I was in dyno. And I think I don't have problem with torque limiting by ecu as my throttle setpoint stay in 80.98 from 3000rpm to +6000rpm until lift gas pedal?

Actually I think we run same injectors, Bosch 0280158123? My target is 14-15psi but we will see how I get there.

- josh@severntuning

- Posts: 17

- Joined: Thu Jul 11, 2019 8:12 pm

Re: MS45 MAF Transfer Curve Comparison

I think the RS4 IAT sensor calibration is floating around out there, although if the resistance is similar then it's not causing your current issue.Juuso wrote: ↑Wed Mar 25, 2020 11:48 am 1. I have checked they have same resistance in 20celsius and from Live Data I have checked in cold mornings it seems to be pretty accurate. Higher temps I can't be sure yet as we have cold weather here at the moment and I haven't tested they for example 35-50 celsius environment but yeah that's good point which I should do to be sure curves match in higher temps.

How are you adjusting the tables? Larger numbers = longer injectionJuuso wrote: ↑Wed Mar 25, 2020 11:48 am 2. I have scaled injectors in "Global injection time correction". I have set which have been flow tested and matched set of injectors so I knew exact flow rates for new injectors and I found flow test measurements for same type of injectors which I had stock and I made calculation between them.

"the correction factor that relates mg/stk to injector pulsewidth; or the 12x16 and 10x12 compensation tables for each site (the hardest way IMHO)"

I think you mean by 12x16 compensation table ip_mff_cor_2 and ip_mff_cor_1 but what tables you mean by 10x12? Those 12x16 adjust have been easy when car was N/A and also now when it's boosted but for some reason ecu just doesn't raise injection time much as needed after 5500rpm and it start to go lean and AFR is 13-13.5 before 6000rpm and it get worse over 6000rpm. I took video from live data while I was in dyno but there can't see same time rpm and injection time but it shows end of the pull injection time start to drop and that time we took pulls only to around 6000rpm not untill limiter because it went lean so badly.

Here is some figures from Load/RPM/Boost(bar) in WOT pull in dyno: 594.8/4000/0.3 , 601.4/4512/0.31 , 621.5/5056/0.33 , 637.3/5504/0.34 , 644.0/5600/0.34 , 629.6/6016/0.4 , 604.0/6240/0.4. At dyno I run without boost tee in that moment and I have 0.3bar spring in my Tial 38mm wastegate. Wastegate obviously opened in those pulls at 3800-4000rpm because there is litle bump in boost chart which dyno data collection have draw.

Have you also adjusted the full load target lambda tables?

Almost 1000 kg/hr is too high for your current setup, which makes me think the MAF scaling is incorrect or you have a boost leak. You should be seeing around 700-750 kg/hr as a rough estimate at your boost level. Have you performed a pressure test on the intake piping? Google search for "Markski pressure test video" and you'll get an idea of the technique the 911 Turbo community uses. Ideally you'll want to disconnect the post-compressor pipe, hook up an end cap with a nipple and pressure gauge, and then use an air compressor to charge the intake piping to your max boost level (1 bar in your case, since that's your end goal). Turn off the compressor so you can listen for leaks. You should only see a small drop in pressure over 20-30 seconds, maybe 1-2 psi. I'm not associated with the company, but I've used https://turboboostleaktesters.com/ in the past with success. I would recommend a boost leak test even if a boost leak isn't suspected... sometimes they can surprise you. My 911 Turbo was hitting full boost by 3500 rpm, but when I performed a pressure test, the intake piping wouldn't hold any pressure. I ended up finding a blown check valve that I otherwise wouldn't have suspected. Now I hit 1.4 bar of boost 500 rpm sooner and IAT has dropped.

However, a boost leak should make the car run rich, which leads me to think it's your MAF scaling or sensor itself which is causing the high kg/hr reading.

Consider checking your fuel pump and logging pressure. I think this is most likely the cause of your issue, since the ECU should be commanding more fuel to meet the lambda target at 1000 kg/hr.

Lastly, not correcting the intake manifold tables will lead to misfires due to a rich condition, and misfires lead to oxygen sensors falsely reading lean conditions. I would multiply the tables by 1.4, since that's your approximate pressure ratio, and scale the other torque-related tables so that you can rule this out as an issue.

You should be able to drop in the values if you're using the MAF hack correctly and it is proven to work. If you're not using the hack, then the curve should peak at 1024 kg/hr at about 4.36V and flat line at 1024 kg/hr all the way to 5V. This is because 1024 kg/hr equates to FFFF in the hex file, which is the largest value the ECU can accommodate. Even at 1 bar of boost, the stock MAF is probably ok if you layer on a bit of extra fuel over 6000 rpm.Juuso wrote: ↑Wed Mar 25, 2020 11:48 am 4. Why I can't adjust it to conversion table for MAF value as isn't that the table where ECU calculates airflow/V right? I didn't say I used it straight which I found from wiki because there is different kghr/V steps in chart than MS45 have so I first wrote it out in excel to get it right. How do you mean I have to align it first as I have RS4 MAF sensor in it original tube not different size tubing? MAF hack is to get ecu capable calculate more than 1024kg/hr right? For example it doesn't really matter if MAF Voltage is 3 or 4.5V at 268.59kg/hr long as it match up in id_maf_tab(coversion table for MAF value) where ecu read kg/hr value from voltage, right?

After all I have m54b22 EU spec MS45 which have whole different MAF than US/EU spec Z4 m54b25 MS45 which tune I'm currently using as base tune. For start I modified MAF table for my stock MAF values to get it running correct when car was full stock except US Z4 2.5i tune.

In my conversion at the moment I use RS4 MAF as blow thru because its basicly imposible to get it to turbo inlet which is lowmount setup in my car because I don't want to delete AC, I'm aware problems which might appear after some time with oil in charge pipes.

81 deg throttle setpoint is max, so you're ok there as far as the ECU not limiting torque. It can get confused and cause misfires leading to a false lean condition due to the tables being incorrect. Those are the same injectors I use, and they work pretty well. I think they will be just enough for flex fuel and the boost levels I'm planning to run, so you should have plenty of headroom.Juuso wrote: ↑Wed Mar 25, 2020 11:48 am 5. At this point I haven't adjusted them as car still runs nicely with stock 2.5 intake manifold tables. I have read many times your big and helpful post from these tables and tuning them and I want to thank you for posting it! I actually have already calculated everything with those instructions for 1bar but obviously it can't be used yet. I have modified ignition tables when I was in dyno. And I think I don't have problem with torque limiting by ecu as my throttle setpoint stay in 80.98 from 3000rpm to +6000rpm until lift gas pedal?

Actually I think we run same injectors, Bosch 0280158123? My target is 14-15psi but we will see how I get there.

-

Juuso

- Posts: 4

- Joined: Thu Feb 20, 2020 3:03 am

Re: MS45 MAF Transfer Curve Comparison

How are you adjusting the tables? Larger numbers = longer injection

Yes, but even when I adjust bigger numbers to table cells in columns around load what ecu calculate in WOT sitsuations rows 5500rpm and 6500rpm it doesn't make effect. Have you rescaled the columns for bigger loads in your setup? I have scaled my last six columns until 1030mg/stk and now I'm thinking does that rescaling really work as I haven't tried to adjust last columns which original values(end of table) would be columns which ecu uses for injection time calculation.

Have you also adjusted the full load target lambda tables?

In my setup I'm not currently using lambda targets at all because my Turbo manifold is 6-1 so I cant use Banks to correct cyls. I have lambdas in my downpipe and I have tried to get it work with them but it doesn't really work as they will start to confuse each other banks and AFR is very unsteady. I have made some changes to Lambda tables and it caused situation where lambda integrators doesn't work when Load exceeds 100mg/stk. But yes I have tested setup with working lambda targets in all situations and while WOT I didn't had problems with unsteady AFR but still had same fueling issue in the end of rpm range.

Almost 1000 kg/hr is too high for your current setup, which makes me think the MAF scaling is incorrect or you have a boost leak. You should be seeing around 700-750 kg/hr as a rough estimate at your boost level. Have you performed a pressure test on the intake piping? Google search for "Markski pressure test video" and you'll get an idea of the technique the 911 Turbo community uses. Ideally you'll want to disconnect the post-compressor pipe, hook up an end cap with a nipple and pressure gauge, and then use an air compressor to charge the intake piping to your max boost level (1 bar in your case, since that's your end goal). Turn off the compressor so you can listen for leaks. You should only see a small drop in pressure over 20-30 seconds, maybe 1-2 psi. I'm not associated with the company, but I've used https://turboboostleaktesters.com/ in the past with success. I would recommend a boost leak test even if a boost leak isn't suspected... sometimes they can surprise you. My 911 Turbo was hitting full boost by 3500 rpm, but when I performed a pressure test, the intake piping wouldn't hold any pressure. I ended up finding a blown check valve that I otherwise wouldn't have suspected. Now I hit 1.4 bar of boost 500 rpm sooner and IAT has dropped.

Yes I think too but it was "video log" which I filmed by my phone from live values at dyno. I have checked video in slow motion now and that MAF value makes bumps when value is rising with rpm and boost and that nearly 1000kg/hr was peak bump moment when gas pedal was lifted. More likely reading was around 820-860kg/hr 6000rpm but yes that's still too much. Yes leak test is good idea and I think I have hardware for testing somewhere in my garage shelf which I made to test my old E36 M50SC setup pipings couple years ago.

However, a boost leak should make the car run rich, which leads me to think it's your MAF scaling or sensor itself which is causing the high kg/hr reading.

Do you have different chart of values for RS4 MAF scaling than the ms4x wiki document? If you have value chart for RS4 MAF I would be happy to compare it to my chart. When I did first testing in dyno N/A with stock maf and stock air filter setup it showed me ~490kg/hr at highest value. At dyno I changed RS4 MAF and K&N filter to test it showed ~540-550kg/hr so it leads to situation where MAF values is wrong.

Consider checking your fuel pump and logging pressure. I think this is most likely the cause of your issue, since the ECU should be commanding more fuel to meet the lambda target at 1000 kg/hr.

I have made fuel pressure test during the dyno. I attached fuelpressure gauge to fuelrail and pressure wasn't the problem in high rpms, it was completely steady. I have checked my live data video from dyno and for some reason 5500-6000rpm injection time stop raising and after 6000rpm it start to drop and 6000-6250rpm it dropped almost 1ms.

Lastly, not correcting the intake manifold tables will lead to misfires due to a rich condition, and misfires lead to oxygen sensors falsely reading lean conditions. I would multiply the tables by 1.4, since that's your approximate pressure ratio, and scale the other torque-related tables so that you can rule this out as a]n issue.

I will do this!

You should be able to drop in the values if you're using the MAF hack correctly and it is proven to work. If you're not using the hack, then the curve should peak at 1024 kg/hr at about 4.36V and flat line at 1024 kg/hr all the way to 5V. This is because 1024 kg/hr equates to FFFF in the hex file, which is the largest value the ECU can accommodate. Even at 1 bar of boost, the stock MAF is probably ok if you layer on a bit of extra fuel over 6000 rpm.

Yes I haven't got MAF hack yet so curve goes flat from 1023.98kg/hr/4.37V. My MAF is currently in charge pipe just before throttle flap because there is no room to do inlet piping for MAF before turbo without removing AC compressor. And as you said earlier Siemens/VDO maf will not last for long in charge pipe as blow thru setup so I don't want to go with it.

81 deg throttle setpoint is max, so you're ok there as far as the ECU not limiting torque. It can get confused and cause misfires leading to a false lean condition due to the tables being incorrect. Those are the same injectors I use, and they work pretty well. I think they will be just enough for flex fuel and the boost levels I'm planning to run, so you should have plenty of headroom.

I think in my case it's not false lean condition as car really goes leaner and leaner when rpm rise and injection time stop/start to drop.

Yes, but even when I adjust bigger numbers to table cells in columns around load what ecu calculate in WOT sitsuations rows 5500rpm and 6500rpm it doesn't make effect. Have you rescaled the columns for bigger loads in your setup? I have scaled my last six columns until 1030mg/stk and now I'm thinking does that rescaling really work as I haven't tried to adjust last columns which original values(end of table) would be columns which ecu uses for injection time calculation.

Have you also adjusted the full load target lambda tables?

In my setup I'm not currently using lambda targets at all because my Turbo manifold is 6-1 so I cant use Banks to correct cyls. I have lambdas in my downpipe and I have tried to get it work with them but it doesn't really work as they will start to confuse each other banks and AFR is very unsteady. I have made some changes to Lambda tables and it caused situation where lambda integrators doesn't work when Load exceeds 100mg/stk. But yes I have tested setup with working lambda targets in all situations and while WOT I didn't had problems with unsteady AFR but still had same fueling issue in the end of rpm range.

Almost 1000 kg/hr is too high for your current setup, which makes me think the MAF scaling is incorrect or you have a boost leak. You should be seeing around 700-750 kg/hr as a rough estimate at your boost level. Have you performed a pressure test on the intake piping? Google search for "Markski pressure test video" and you'll get an idea of the technique the 911 Turbo community uses. Ideally you'll want to disconnect the post-compressor pipe, hook up an end cap with a nipple and pressure gauge, and then use an air compressor to charge the intake piping to your max boost level (1 bar in your case, since that's your end goal). Turn off the compressor so you can listen for leaks. You should only see a small drop in pressure over 20-30 seconds, maybe 1-2 psi. I'm not associated with the company, but I've used https://turboboostleaktesters.com/ in the past with success. I would recommend a boost leak test even if a boost leak isn't suspected... sometimes they can surprise you. My 911 Turbo was hitting full boost by 3500 rpm, but when I performed a pressure test, the intake piping wouldn't hold any pressure. I ended up finding a blown check valve that I otherwise wouldn't have suspected. Now I hit 1.4 bar of boost 500 rpm sooner and IAT has dropped.

Yes I think too but it was "video log" which I filmed by my phone from live values at dyno. I have checked video in slow motion now and that MAF value makes bumps when value is rising with rpm and boost and that nearly 1000kg/hr was peak bump moment when gas pedal was lifted. More likely reading was around 820-860kg/hr 6000rpm but yes that's still too much. Yes leak test is good idea and I think I have hardware for testing somewhere in my garage shelf which I made to test my old E36 M50SC setup pipings couple years ago.

However, a boost leak should make the car run rich, which leads me to think it's your MAF scaling or sensor itself which is causing the high kg/hr reading.

Do you have different chart of values for RS4 MAF scaling than the ms4x wiki document? If you have value chart for RS4 MAF I would be happy to compare it to my chart. When I did first testing in dyno N/A with stock maf and stock air filter setup it showed me ~490kg/hr at highest value. At dyno I changed RS4 MAF and K&N filter to test it showed ~540-550kg/hr so it leads to situation where MAF values is wrong.

Consider checking your fuel pump and logging pressure. I think this is most likely the cause of your issue, since the ECU should be commanding more fuel to meet the lambda target at 1000 kg/hr.

I have made fuel pressure test during the dyno. I attached fuelpressure gauge to fuelrail and pressure wasn't the problem in high rpms, it was completely steady. I have checked my live data video from dyno and for some reason 5500-6000rpm injection time stop raising and after 6000rpm it start to drop and 6000-6250rpm it dropped almost 1ms.

Lastly, not correcting the intake manifold tables will lead to misfires due to a rich condition, and misfires lead to oxygen sensors falsely reading lean conditions. I would multiply the tables by 1.4, since that's your approximate pressure ratio, and scale the other torque-related tables so that you can rule this out as a]n issue.

I will do this!

You should be able to drop in the values if you're using the MAF hack correctly and it is proven to work. If you're not using the hack, then the curve should peak at 1024 kg/hr at about 4.36V and flat line at 1024 kg/hr all the way to 5V. This is because 1024 kg/hr equates to FFFF in the hex file, which is the largest value the ECU can accommodate. Even at 1 bar of boost, the stock MAF is probably ok if you layer on a bit of extra fuel over 6000 rpm.

Yes I haven't got MAF hack yet so curve goes flat from 1023.98kg/hr/4.37V. My MAF is currently in charge pipe just before throttle flap because there is no room to do inlet piping for MAF before turbo without removing AC compressor. And as you said earlier Siemens/VDO maf will not last for long in charge pipe as blow thru setup so I don't want to go with it.

81 deg throttle setpoint is max, so you're ok there as far as the ECU not limiting torque. It can get confused and cause misfires leading to a false lean condition due to the tables being incorrect. Those are the same injectors I use, and they work pretty well. I think they will be just enough for flex fuel and the boost levels I'm planning to run, so you should have plenty of headroom.

I think in my case it's not false lean condition as car really goes leaner and leaner when rpm rise and injection time stop/start to drop.

- josh@severntuning

- Posts: 17

- Joined: Thu Jul 11, 2019 8:12 pm

Re: MS45 MAF Transfer Curve Comparison

There are multiple MAF curves for the same part number, and multiple sensors that share the same part number. There's a "large diameter housing" RS4 version and a smaller diameter housing version. If you're using the RS4 curve, make sure you're using the RS4 MAF and not the B5 S4 MAF. https://www.ecstuning.com/b-bosch-parts ... 3471k~bos/ although there are cheaper sources out there.

What are your fuel trims?

You absolutely need to tune off of a full load lambda target. You'll just spin your wheels (and not in a good way) if you try to work around that on MS45. There are too many factors that require optimization.

The 6-1 log manifold is definitely going to affect your tune. Have you experimented with the MS43 parameters that allow adjustment of the number of O2 sensors?

What are your fuel trims?

You absolutely need to tune off of a full load lambda target. You'll just spin your wheels (and not in a good way) if you try to work around that on MS45. There are too many factors that require optimization.

The 6-1 log manifold is definitely going to affect your tune. Have you experimented with the MS43 parameters that allow adjustment of the number of O2 sensors?

Last edited by josh@severntuning on Mon Mar 30, 2020 3:31 pm, edited 1 time in total.

- josh@severntuning

- Posts: 17

- Joined: Thu Jul 11, 2019 8:12 pm

Re: MS45 MAF Transfer Curve Comparison

Here's a 512x1 RS4 MAF curve I pulled off of a WinOLS project. It's pretty close to the RS4 curve available on e46fanatics, other than ~200 kg/hr offset I've estimated. If you want to use mine, you'll need to delete every other cell.

You do not have the required permissions to view the files attached to this post.

-

SakhrHendawi

- Posts: 12

- Joined: Fri Apr 10, 2020 9:49 am

Re: MS45 MAF Transfer Curve Comparison

Juuso wrote: ↑Wed Mar 25, 2020 11:48 am I have checked they have same resistance in 20celsius and from Live Data I have checked in cold mornings it seems to be pretty accurate. Higher temps I can't be sure yet as we have cold weather here at the moment and I haven't tested they for example 35-50 celsius environment but yeah that's good point which I should do to be sure curves match in higher temps.

Were you able to test the accuracy of the IAT sensor in higher temps since you last posted? I'm interested in the RS4 MAF if the IAT can be utilized

-

sda2

- Posts: 1

- Joined: Wed Dec 22, 2021 2:26 pm

Re: MS45 MAF Transfer Curve Comparison

I have to jump in here even though the topic is two years old.

MS43/45 and ME7 use different methods of how they actually get the data from the ADC input channel.

For the data to match best, I used the original RS4 scale and interpolated it to MS42/43/45 voltage axis.

Btw. the data used by Audi in the RS4 binary is also different from the official scale that Bosch gave us in the very beginning.

MS43/45 and ME7 use different methods of how they actually get the data from the ADC input channel.

For the data to match best, I used the original RS4 scale and interpolated it to MS42/43/45 voltage axis.

Btw. the data used by Audi in the RS4 binary is also different from the official scale that Bosch gave us in the very beginning.

-

Gino Rama

- Posts: 1

- Joined: Tue Aug 13, 2024 5:35 am

Re: MS45 MAF Transfer Curve Comparison

What injector do you use for your setup? Oem?

Juuso wrote: ↑Tue Mar 17, 2020 4:51 am I have Audi RS4(b5) MAF in my EU E60 520i(m54b22 Siemens MS45) turbo. It was hard to find Flow/Voltage curve for it and curve which I found from internet wasn't perfect. In stock n/a conditions it showed ~50kg/hr higher amount of air just before rpm limiter than stock MAF but I have proceed with it. Now at the moment I have 0.4-0.5bar boost and it already showed me 998kg/hr which seems a bit high to me but is it?

I'm going to raise boost to 1bar when dme calculations is capable for that and I have solved my other fueling issue which starts from 5500rpm->